3D Printing Best Infill Pattern

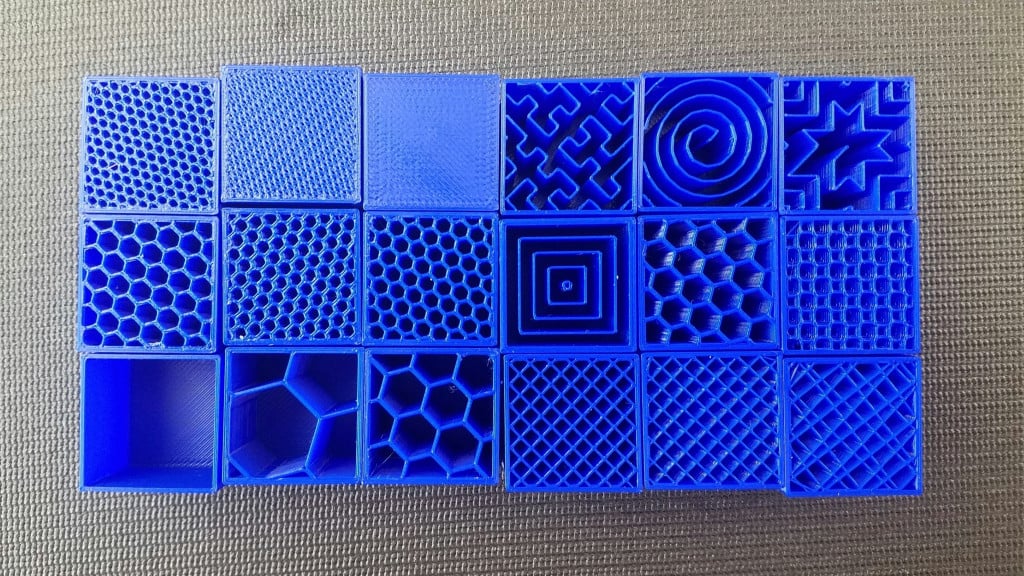

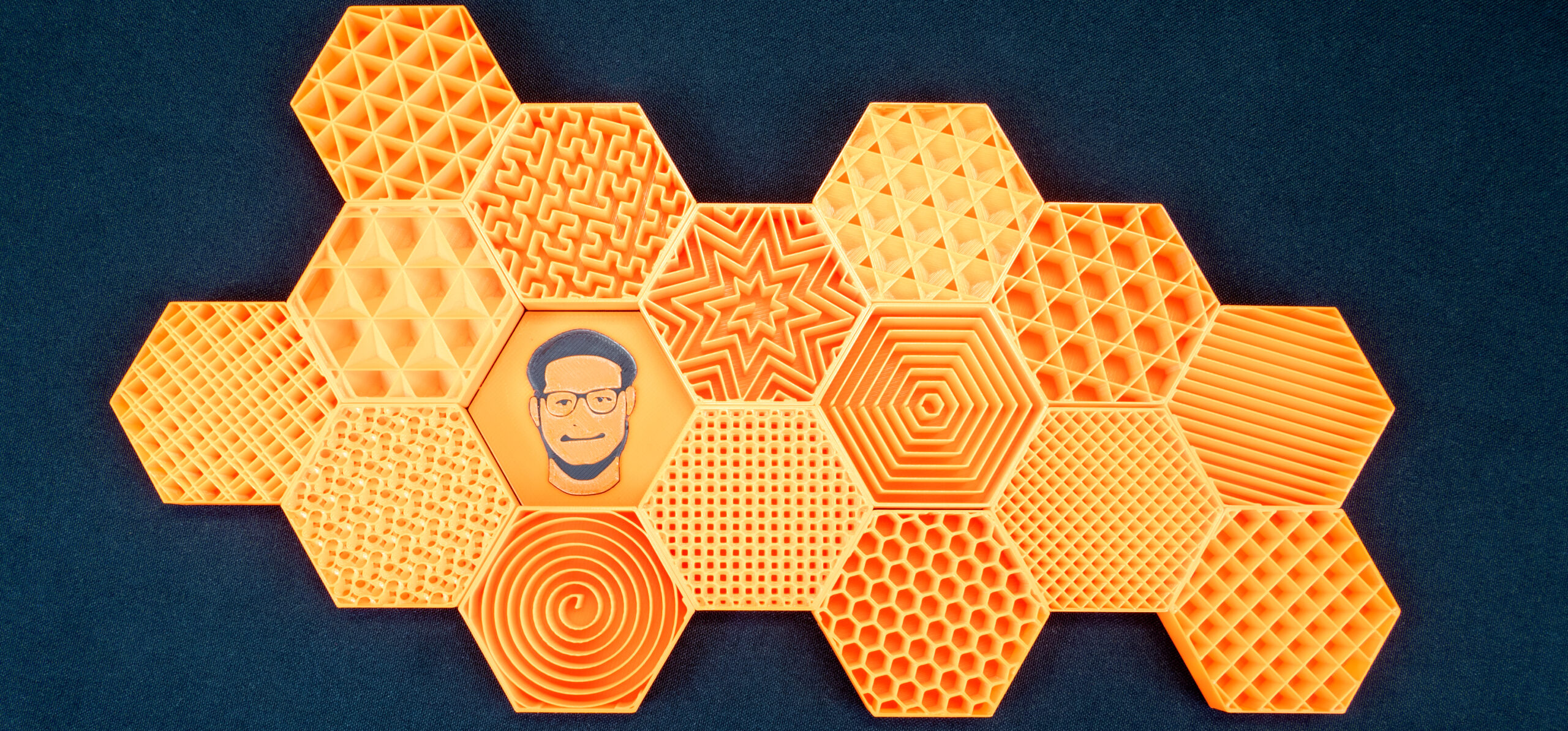

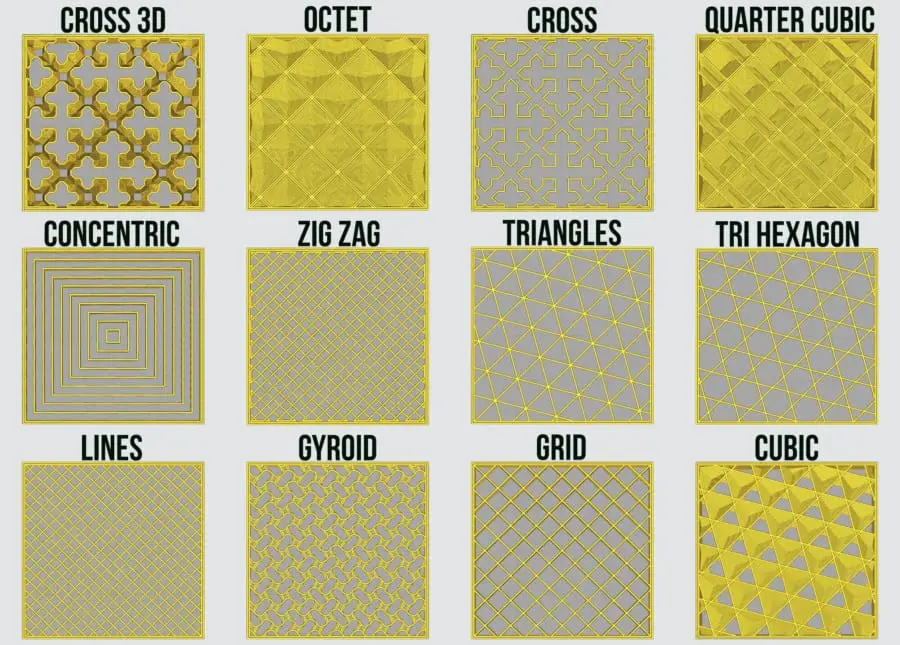

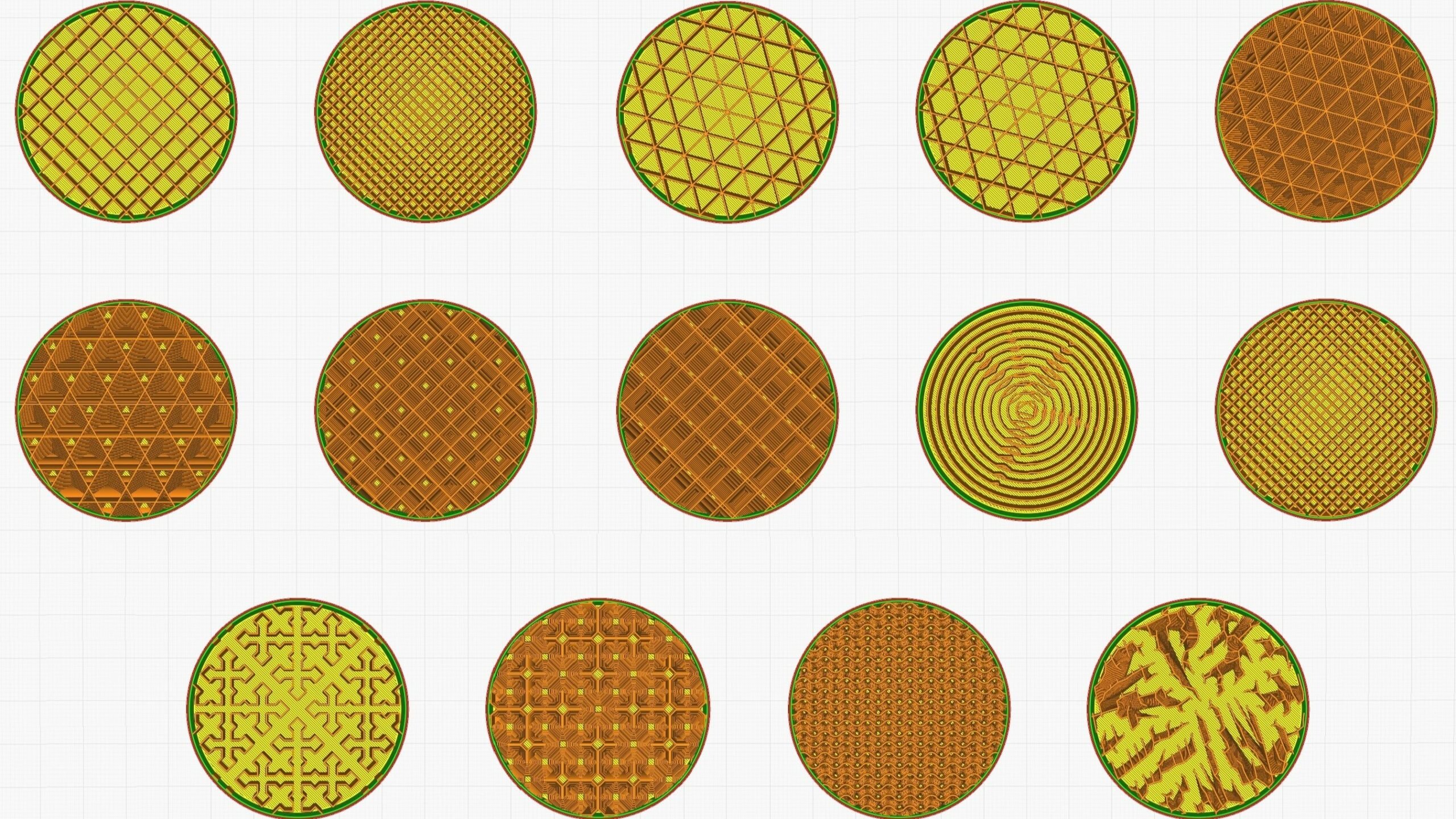

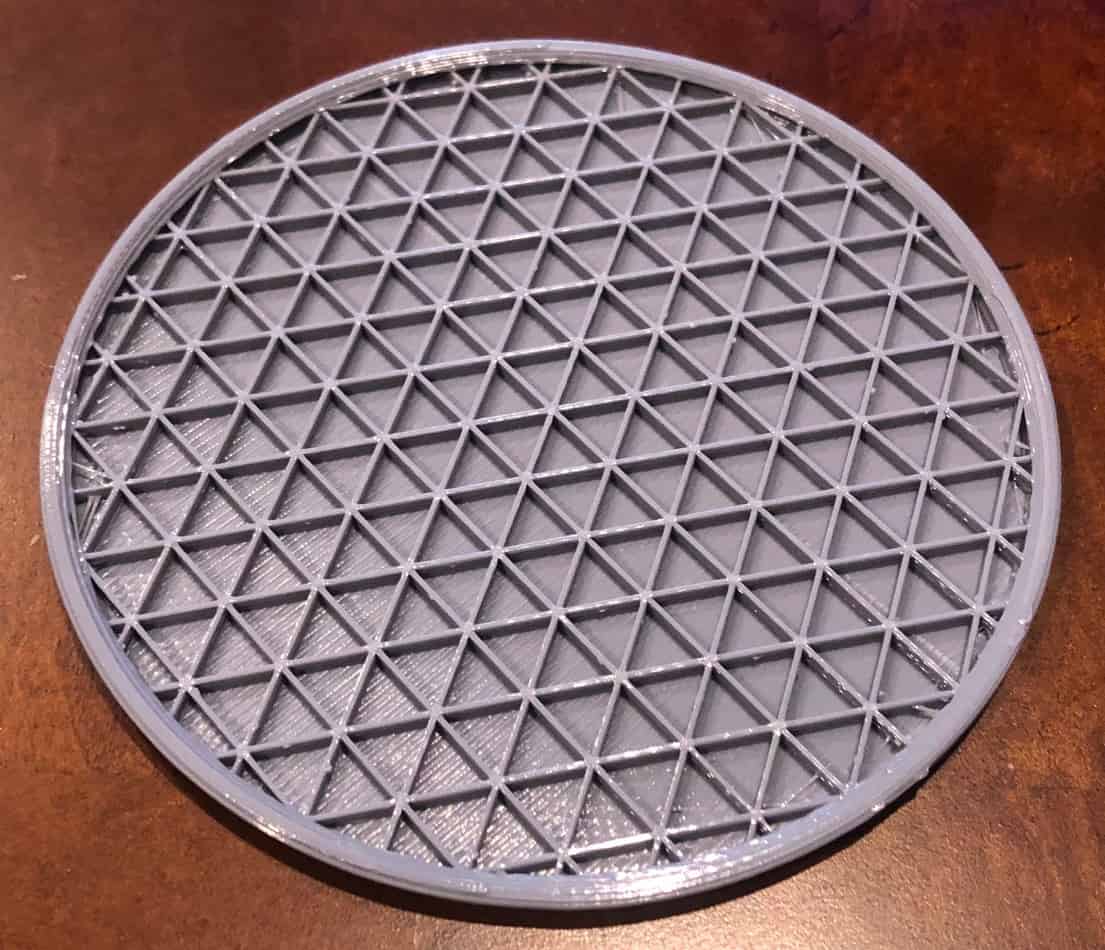

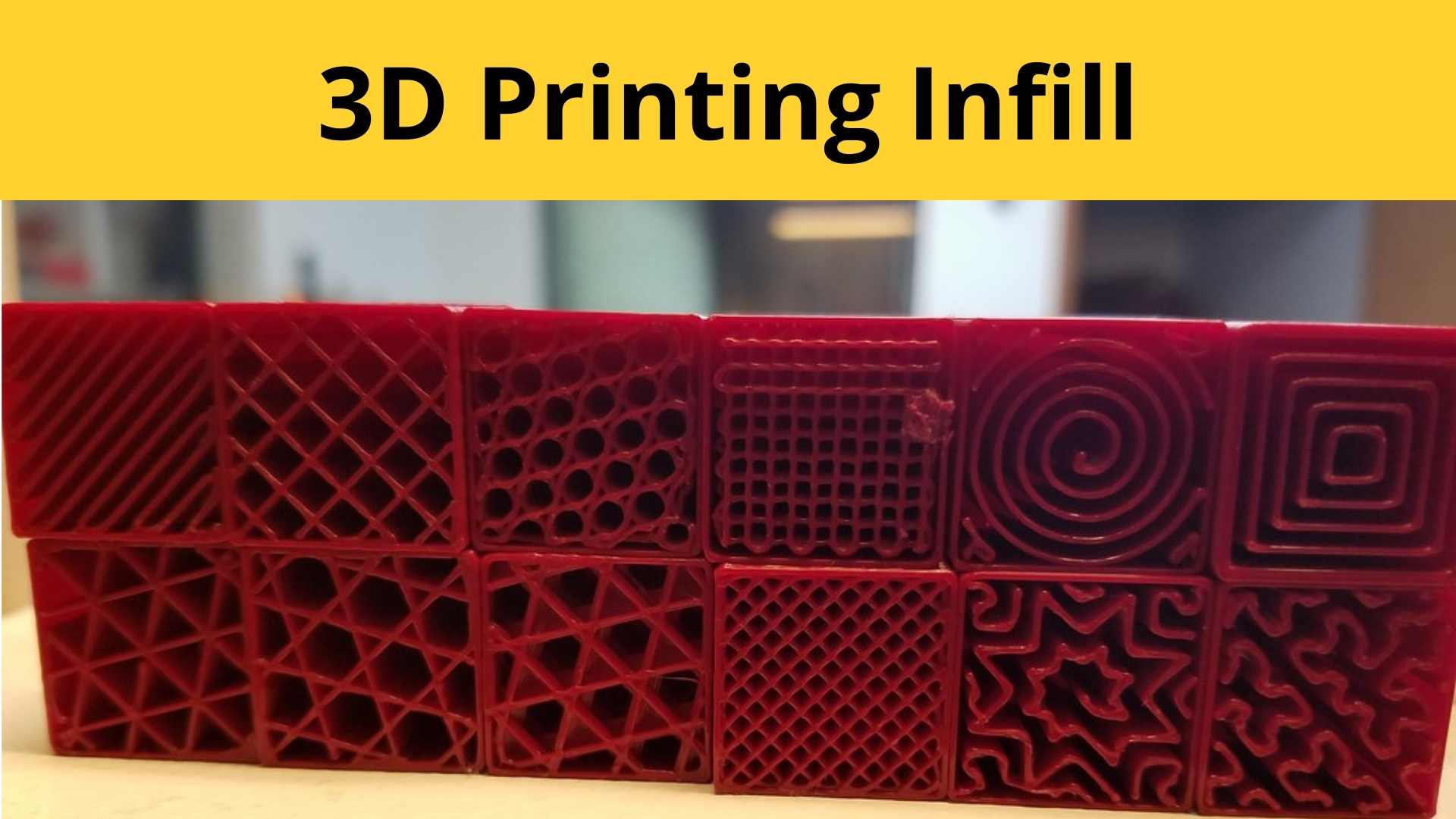

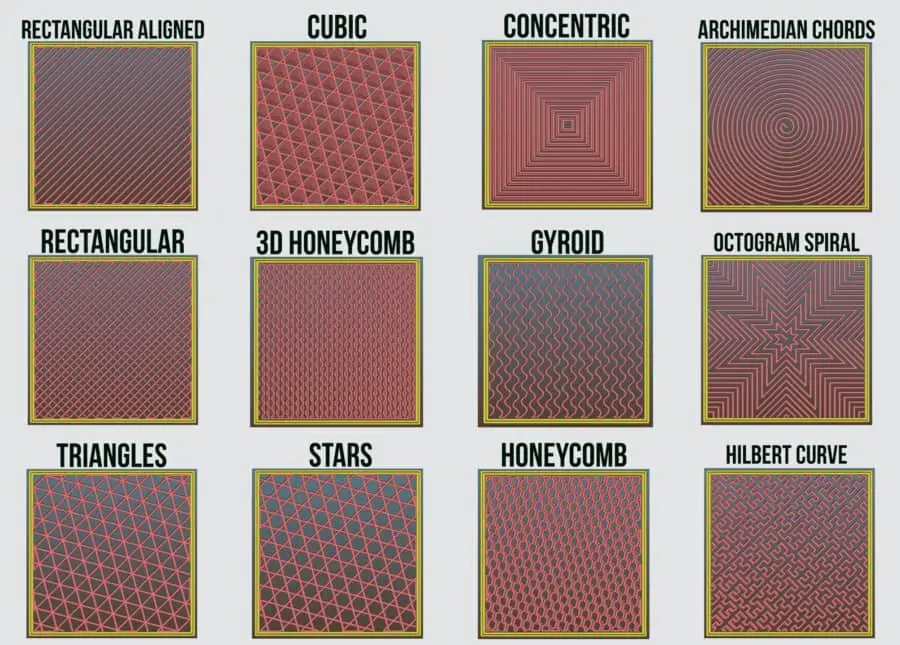

3D Printing Best Infill Pattern - Both patterns are overall great picks, with decent strength, a low print time, and low weight. You can use it with any model, knowing it will be structurally sound without using too much filament. This pattern consists of only one line, with the lack of directional changes saving the printer time. For models that don’t need strength, lines and grid infill patterns are the best because they’re fast to. For speed the best infill pattern is the lines pattern, while for strength, cubic. Infill is the internal structure of a 3d printed object, hidden from view but vital in providing strength and support. Start by selecting an infill pattern that best suits your project’s needs. Three slicers’ 3d infill pattern options of most popular 3 slicers. How to choose infill percentage in 3d printing. Web 3d printed models are rarely printed solid (100% infill) or completely hollow. Because geometries are not all strong, the infill pattern you choose affects part strength. Instead, we use a method that fills the inside of an object with a sparse supporting structure. Using shell thickness to reduce infill percentage. Types of 3d printing infills. When you determine the function of your 3d printed part, the best infill pattern will vary. Web the fastest 3d printing infill pattern is the concentric. Web basic object sections. For general use 3d printing, a basic but reliable pattern that uses little filament like grid is a solid option, while concentric is best for flexible parts, and gyroid rises above the rest if you need strength and support in all. Read on to learn more about it. For example, a 10% infill means 10% of your print is solid plastic, with the remaining 90% of the part’s inside structure left empty. You can use it with any model, knowing it will be structurally sound without using too much filament. Find the best cura infill patterns for your application. Web basic object sections. Continue reading to learn about the 5 strongest infill patterns! Web the best 3d printing infill pattern shape depends on what type of part you are printing and for. How to choose infill percentage in 3d printing. For models that don’t need strength, lines and grid infill patterns are the best because they’re fast to. Infill is the internal structure of a 3d printed object, hidden from view but vital in providing strength and support. Read on to learn about the strongest infill patterns! Types of 3d printing infills. Web 1 infill basics. This newly released infill is best for objects that don’t need great mechanical stability. For models that don’t need strength, lines and grid infill patterns are the best because they’re fast to. When you determine the function of your 3d printed part, the best infill pattern will vary. Web the cubic infill pattern is the best. Infill provides internal support for top layers, which would otherwise have to. Read on to learn more about it. When you determine the function of your 3d printed part, the best infill pattern will vary. Find the best cura infill patterns for your application. Web improve the quality of your 3d prints by choosing the ideal infill pattern based on. Overview of all infill patterns available in cura, source: Find the best cura infill patterns for your application. Instead, we use a method that fills the inside of an object with a sparse supporting structure. Because geometries are not all strong, the infill pattern you choose affects part strength. Web choosing a strong infill pattern is normally relatively easy. Web 14 best cura infill patterns based on strength. It’s a percentage number that shows how much plastic and how much empty room your parts have. Web in 3d printing, infill plays an important role in a part's strength, structure, and weight. Other options for 3d print infill pattern. Web infill can look cool, add strength, and save money, but. Web choosing the best infill pattern. Read on to learn about the strongest infill patterns! There are patterns, however, that are incredibly common and that you can expect from any slicer software. Because geometries are not all strong, the infill pattern you choose affects part strength. There are many different types of infills for 3d printing. In cura and prusaslicer, the fastest infill pattern is the lightning. Read on to learn about the strongest infill patterns! Web most people consider gyroid and cubic to be the most efficient infill patterns. Do take this ranking with a grain of salt. There are many different types of infills for 3d printing. In cura and prusaslicer, the fastest infill pattern is the lightning. Slicers provide numerous infill pattern possibilities, but not all produce sturdy 3d prints. Density per material used (better support for top layers with less material) visuals; Cubic, gyroid, or cubic subdivision. Web if you want your print to be as strong as possible, then a cubic or gyroid infill. To achieve the best results for your 3d printing projects, we suggest following these infill settings when using cura: There is a little more to infill patterns. Density per material used (better support for top layers with less material) visuals; In fact, gyroid and cubic infill patterns offer a very good balance between strength, filament usage, and speed for most. Three slicers’ 3d infill pattern options of most popular 3 slicers. Web 3d printed models are rarely printed solid (100% infill) or completely hollow. Types of 3d printing infills. These are the best infill patterns for certain priorities: Web in 3d printing, infill allows you to adjust the amount of material inside of your objects. However, choosing one should depend on what you’re printing and why. How to choose infill percentage in 3d printing. Web the cubic infill pattern is the best infill pattern overall. 3d print infill patterns for external fill. This newly released infill is best for objects that don’t need great mechanical stability. Density per material used (better support for top layers with less material) visuals; Continue reading to learn about the 5 strongest infill patterns! If you want maximum strength and don’t care about speed, honeycomb patterns may be a better option. For example, a 10% infill means 10% of your print is solid plastic, with the remaining 90% of the part’s inside structure left empty. Cubic, gyroid, or cubic subdivision. You can use it with any model, knowing it will be structurally sound without using too much filament.3D Printing Infill The Basics Simply Explained All3DP

Best 3d printing infill pattern what's your optimal choise?

3D Print Infill Patterns Explained The 3D Bros

Cura Guide to the Best Infill Patterns All3DP

Best 3D Printing Infill Pattern Complete Details Inside

Best 3D Printing Infill Pattern

Infill Pattern Comparison r/3Dprinting

Guide to 3D printing infill settings its pattern, percentage and

3D Print Infill Patterns Explained The 3D Bros

3D Print Infill Pattern Which One Is The Best For Your Needs

Cura’s Latest Version (5.3) Includes 14 Types Of Infill Patterns That Vary In Terms Of Strength, Flexibility, And Final Surface Smoothness Of The Printed Object.

Read On To Learn More About It.

Web The Best 3D Printing Infill Pattern Shape Depends On What Type Of Part You Are Printing And For What Application.

Web What Is The Best 3D Print Infill Pattern To Use?

Related Post: