Patterns Of Damascus Steel

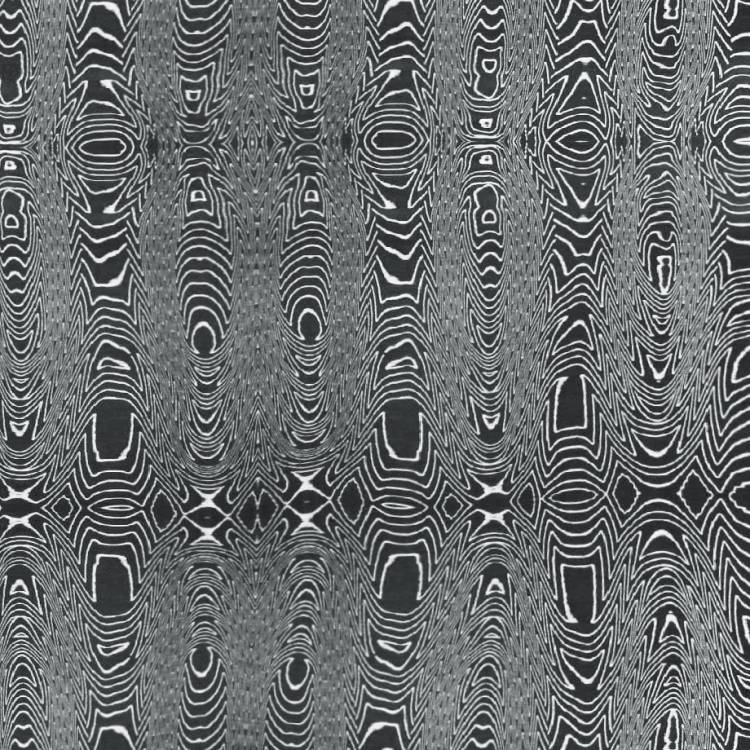

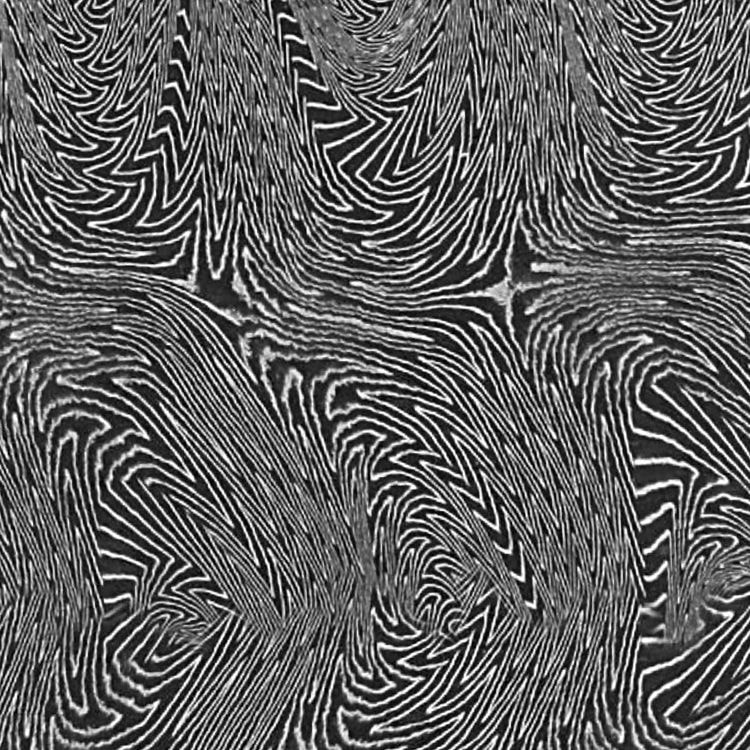

Patterns Of Damascus Steel - Basic patterns like random patterns, twist patterns, ladder patterns, and raindrop patterns can. Web celebrated for its unique wavy or watery pattern, damascus steel is a testament to the artistry and skill involved in swordsmithing. In our tomahawk building class you will learn how to forge weld your tomahawk and forge it into shape, heat treating and tempering your tomahawk. Web step into the world of damascus steel and explore the various types of patterns available! Today, blacksmiths make damascus by welding different types of steels together and working them into folded layers. Find out everything you need to know about them, from how they're made to different patterns. Are damascus steel knives worth it? No two swords are ever alike. Web the hallmark pattern became known as damask, or damascene. Europeans’ interest in copying the steel grew around 1800, just as the art of making it was vanishing in the islamic world. We provide detailed descriptions of the different patterns and finishes, so you can make an informed decision when picking a damascus steel blade for your next project. Web the hallmark pattern became known as damask, or damascene. The answer lies in the process of etching. But what happens after your blade is forged, ground, and sanded? But what exactly are damascus steel patterns, how are they made, and which should you choose? Basic patterns like random patterns, twist patterns, ladder patterns, and raindrop patterns can. Web while there are numerous patterns made in a variety of ways, here are five of the distinctive patterns commonly seen in damascus steel: Are damascus steel knives worth it? Web how to make basket weaves, spider webs and radial w’s. To help you plan your projects, we’ve compiled some before and after photos to show you how a pattern transforms from the raw billet to the finished product. Copies of items that are copyrighted. Web how to make basket weaves, spider webs and radial w’s. Blades made of damascus steel, however, have been around for centuries. The former allows for compression of the material to absorb an increase of energy that would otherwise minimize or eliminate failure in the integrity of the blade. Depending on the steels included. Web damascus steel aesthetically stands out, with each blade having a unique pattern. But what happens after your blade is forged, ground, and sanded? ‘damask’ the patterns were called, hence the name damascus steel. فولاذ دمشقي) is the forged steel of the blades of swords smithed in the near east from ingots of carbon steel imported from southern india or. One of the most distinctive and intricate patterns of damascus steel is the feathered pattern. Web the hallmark pattern became known as damask, or damascene. Web celebrated for its unique wavy or watery pattern, damascus steel is a testament to the artistry and skill involved in swordsmithing. Damascus steel is legendary steel recognized for its streaked watered design and. Read. In this article, we’ll describe how damascus steel gets made and the most common patterns that artisans work into it. Damascus steel is legendary steel recognized for its streaked watered design and. فولاذ دمشقي) is the forged steel of the blades of swords smithed in the near east from ingots of carbon steel imported from southern india or made in. The former allows for compression of the material to absorb an increase of energy that would otherwise minimize or eliminate failure in the integrity of the blade. But what happens after your blade is forged, ground, and sanded? Blades made of damascus steel, however, have been around for centuries. Europeans’ interest in copying the steel grew around 1800, just as. Today, blacksmiths make damascus by welding different types of steels together and working them into folded layers. In this article, we’ll describe how damascus steel gets made and the most common patterns that artisans work into it. We provide detailed descriptions of the different patterns and finishes, so you can make an informed decision when picking a damascus steel blade. In our tomahawk building class you will learn how to forge weld your tomahawk and forge it into shape, heat treating and tempering your tomahawk. The former allows for compression of the material to absorb an increase of energy that would otherwise minimize or eliminate failure in the integrity of the blade. How to make damascus steel patterns. These patterns. ‘damask’ the patterns were called, hence the name damascus steel. Web damascus steel patterns are beautifully crafted on kitchen knives. These patterns are often used in the production of knives, swords, and other metal objects. Read on the different damascus patterns and how they are formed. But what exactly are damascus steel patterns, how are they made, and which should. Read on the different damascus patterns and how they are formed. These patterns are often used in the production of knives, swords, and other metal objects. But what happens after your blade is forged, ground, and sanded? Blades made of damascus steel, however, have been around for centuries. Web no matter the niceties of its origin, knives made of damascus. Web pattern weld damascus vs. There are two available options for this class one of our standard tomahawks or one of our hawk killers. Web damascus patterns refer to the wavy or swirling designs that are created when two or more different types of metal are forged together and then manipulated to create a unique pattern. Web damascus steel patterns. Web the hallmark pattern became known as damask, or damascene. Copies of items that are copyrighted. Web celebrated for its unique wavy or watery pattern, damascus steel is a testament to the artistry and skill involved in swordsmithing. In this article, we’ll describe how damascus steel gets made and the most common patterns that artisans work into it. Europeans’ interest in copying the steel grew around 1800, just as the art of making it was vanishing in the islamic world. Find out everything you need to know about them, from how they're made to different patterns. These patterns are often used in the production of knives, swords, and other metal objects. There are two available options for this class one of our standard tomahawks or one of our hawk killers. What is damascus steel back then, and how is it different from what we known now? Web no matter the niceties of its origin, knives made of damascus steel are prized today for both their physical characteristics and their otherworldly designs. But what exactly are damascus steel patterns, how are they made, and which should you choose? Basic patterns like random patterns, twist patterns, ladder patterns, and raindrop patterns can. No two swords are ever alike. Today, blacksmiths make damascus by welding different types of steels together and working them into folded layers. Web damascus steel aesthetically stands out, with each blade having a unique pattern. The former allows for compression of the material to absorb an increase of energy that would otherwise minimize or eliminate failure in the integrity of the blade.Damascus Steel Pattern

Damascus steel Wikipedia

Damascus Steel Sharkstooth Pattern

Damascus Steel Patterns

Types of Damascus Steel Complete Guide 2024

Damascus Steel Patterns F.N. Sharp Blog

How To Make Damascus Steel Patterns UNUGTP News

Damascus Steel Pattern 2 Pack SVG and Pngtransparent Etsy

Damascus Steel Pattern

Damascus Steel Pattern

What We Will Not Make.

Are Damascus Steel Knives Worth It?

We Provide Detailed Descriptions Of The Different Patterns And Finishes, So You Can Make An Informed Decision When Picking A Damascus Steel Blade For Your Next Project.

فولاذ دمشقي) Is The Forged Steel Of The Blades Of Swords Smithed In The Near East From Ingots Of Carbon Steel Imported From Southern India Or Made In Production Centers In Sri Lanka Or Khorasan, Iran.

Related Post: